BIRABAT Transformers provides services of manufacturing of 36 kV high voltage and from 25 to 2500 kVA Distribution and up to 2500 kVA Power Transformers at 7000 m2 open and 4000 m2 closed area in accordance with the cooling systems specified in the related standard via its experienced staff and quality equipments for its customers in three-phase and single-phase, oiled distribution and power transformers sector. Moreover, BIRABAT Transformers also manufactures special type oiled transformers as required by customers.

BIRABAT Transformers manufacture DISTRIBUTION TRANSFORMERS with power between 25 kVA and 2500 kVA, up to 6, 3-11-20-36 kV voltage level, complying with TS, IEC, ANSI and BS standards and national voltage levels as required by customers, HERMETIC type fully closed to atmosphere or EXPANSION TANK type open to atmosphere.

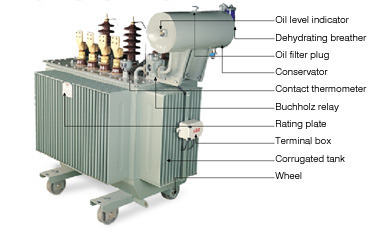

Three-Phase, 25-2500 kVA Transformers with Oil Expansion Tank

It is cored type of manufactured of M5, M4 and M3 silicon alloyed sheets with thicknesses 0.30, 0.27 and 0.24 mm if which crystals are directed. 45 degree inclined cut sheets are used for transition zones of magnetic circuit. All sheets used in magnetic circuit are cut and stored by CNC controlled cutting machine and magnetic circuit is formed by allocation of magnetic circuit is handled by a method called step-lab and which reduces iron losses to the minimum level. Core is aligned by cross and longitudinal step-lab applications.

Leg and yoke cuts are equal and round as multi-layered and theoretically.

Noise levels of core sheets is reduced to the minimum level by fixing by steel pins which pass through U profile and yoke insulated pipes.

Modern winding machines are used.

Distribution Transformer Windings:

Cover insulation is provided by improved rosin paper thermally for low voltage winding conductor copper plate windings.

High voltage winding conductor copper Windings are enamel covered round copper wires and insulation paper is covered flat copper wire. Layer windings are wound by means of computer controlled full automatic machines. Layer. insulation is achieved as wedges by strip electrical insulation papers (electrical craft, thermally improved craft and rosin thermal paper). The created layer insulation not only increases the strength against excessive voltage but also enables to have void-free, solid perfect properties.

Power Transformer Windings:

The winding conductor for both low voltage and high voltage is is copper. The windings are wound as layer winding, continuous disc winding, helical or screw winding depending on the power of transformer by using copper wires covered by insulation papers.

For transformers of which core and bobbins are ready bobbins are mounted by tightening on the core and against each other by means of bars for the purpose of carrying radial loads in order to form the active part and upper yoke is installed. Meanwhile bobbins are equipped with the mechanism for getting protected against axial loads. The active part is prepared for the oven process by carrying out necessary welding and connecting work on the setting edges of direction switch or degree switch via silver electrodes. The active part is dried in the oven by air circulation method in a program frame depending on the power and voltage of the transformer for the purpose of eliminating humidity on solid conducting materials.

We use cookies to make your experience much better!. By continuing to use this site, you accept our use of cookies.